Kitagawa

Kitagawa Iron Works Ltd (KIW) is a Japanese mixed engineering group founded some 75 years ago and listed on the Tokyo stock exchange.

Its products cover machine tool accessories, building materials, a foundry and construction equipment.

In 1982 Kitagawa Europe Ltd (KEL) was founded as a joint venture between KIW and S. Threipland to promote the machine tool accessory products firstly in the UK and then by 1985 throughout Europe, Middle East, India and Africa via a distributor network.

In 2001 KEL opened its own offices in Dusseldorf Germany to deal in Germany and the ex Eastern Block countries and in 2007 KEL opened an office in Pune, India to trade directly throughout India.

KEL's founding motto is to supply quality products and to provide a high level of service to all its customers.

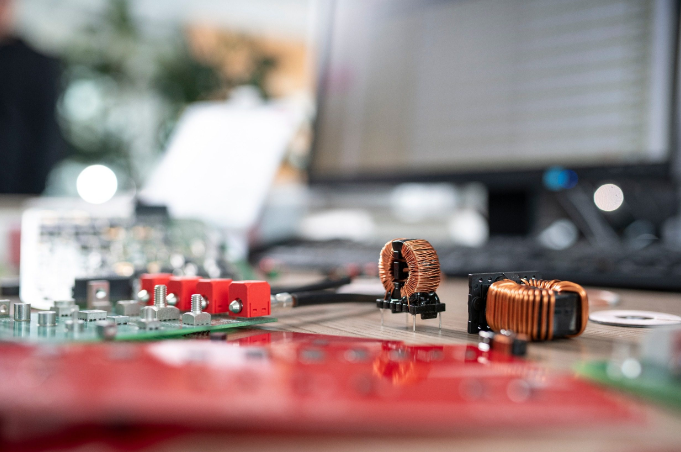

Kitronik

Kitronik create high quality products and resources for education and makers.

We specialise in electronic project kits and also stock the microbit and a range of accessories, plywood, e-textiles, Perspex, clocks and much more.

We aim to inspire & engage people of all abilities to further their knowledge of Electronics, Coding & Design by offering a well designed, well manufactured, innovative product range and free resources. All backed by detailed product descriptions, knowledgeable staff and fast delivery.

Klein Tools

Klein Tools is a company that makes products that can be counted on. Their only focus is on making hand tools that can stand up to the demands of the professionals who use them every day. Klein Tools uses superior workmanship, the highest quality materials, and keep their manufacturing as close to home as they can. Their hand tools can always be relied on to deliver all the performance, durability and precision needed to get a job done right.

KNIPEX

Less is more: we concentrate on one single product group and in this way we achieve appreciable benefits in quality and performance.

That is why Knipex is the world's leading brand in pliers today.

People in more than 100 countries work with Knipex pliers – and this figure is on the increase.

knitter-switch

Since its foundation in 1966 knitter-switch has remained at the forefront of switch technology. Highly specialized we today offer an unrivalled range of switching solutions: toggle switches, pushbutton switches, tact switches, slide switches, dual-in-line switches, rotary coded switches, rotary switches, encoders and snap action switches. Membranes, rubber keymats and steel keyboards complement our product range and we continue to design new switching solutions, employing the latest technologies and materials.

Knoll Systems

Knowles

As a leader in several industries, we see our role as pushing the industry forward, constantly redefining the gold standard through products and services that help our customers enhance their technology solutions. At our core, Knowles is unified by a spirit of innovation that permeates every solution we build, coming together to empower more efficient products.

KNOWLES ACOUSTICS

Knowles Acoustics designs subminiature microphone and speaker technology for the hearing health industry, mobile, automotive, consumer electronics, sensors and instrumentation, civil communications, military, medical and specialty applications.

KOA Speer

Kodenshi Corp.

Kontron AG

Kontron is a global leader in embedded computing technology (ECT). As a part of technology group S&T, Kontron offers a combined portfolio of secure hardware, middleware and services for Internet of Things (IoT) and Industry 4.0 applications. With its standard products and tailor-made solutions based on highly reliable state-of-the-art embedded technologies, Kontron provides secure and innovative applications for a variety of industries. As a result, customers benefit from accelerated time-to-market, reduced total cost of ownership, product longevity and the best fully integrated applications overall.

Kopex International

Founded in Slough in 1947 Kopex International has been at the leading edge of electrical conduit systems for over 50 years.

As a world leader, the company offers an outstanding range of metallic and non-metallic conduits as well as complementary fittings and other accessories. In this way, Kopex provides a one-stop-shop for all your electrical conduit needs - whatever your business.

Kopin Corp.

Kordis Media Co., Ltd

Korenix Technology Co., Ltd

Korenix is an industrial Ethernet hardware manufacturer and a industrial networking solutions provider based in Taiwan. Korenix UK is the company’s extension in the United Kingdom. In Partnership with industrial data communication specialist MAC-Solutions, Korenix UK deals with all distribution of Korenix products and all product support in the United Kingdom.

Korenix built its reputation on the innovative Power over Ethernet - JetPoE series, and further strengthened its market position by providing complete industrial networking solutions on its embedded ranges – Layer 3 switches, Wireless, IP 67 / 68 switches, network embedded computers, PoE interface card, and IO products.

As a result of an outstanding track record, Korenix now has an impressive portfolio of customers across the globe, from Asia, Europe, North America, Africa, to the Middle East.

Korvis

Headquartered in Corvallis, Oregon, Korvis consists of an 120,000 square foot manufacturing and engineering facility, complete with an in-house machine shop, fabrication shop, optics lab, and clean room assembly space. Korvis serves global markets.